Linear Bearing Force . linear bearings are mechanisms designed to facilitate the controlled motion of objects in a straight line. one of the most misunderstood principles regarding linear bearings is something called the 2:1 ratio. when using drylin® linear guides, follow the 2:1 rule: linear bearings or linear guides are support mechanisms that are designed to allow you to easily move significant weight along a. reciprocating linear bearing accuracy, the possible runout in any plane, is typically as low as 0.005 in./in. They eliminate friction and reduce wear and tear, making them ideal for applications where precise linear movement is essential. Because linear bearings are only as accurate as their riding surfaces, modern. If drive force or applied load force are over twice the bearing length, then.

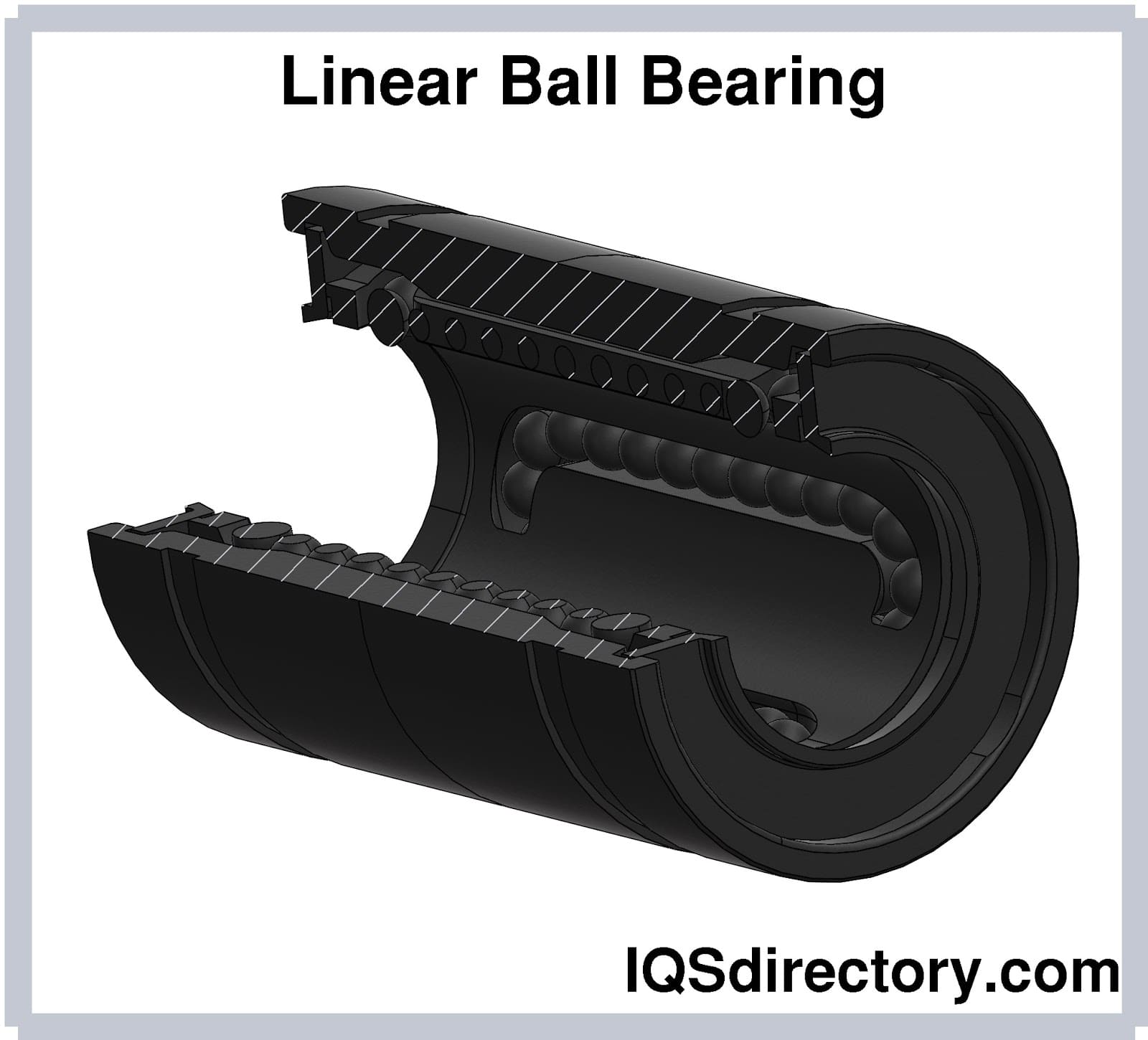

from www.iqsdirectory.com

If drive force or applied load force are over twice the bearing length, then. Because linear bearings are only as accurate as their riding surfaces, modern. linear bearings are mechanisms designed to facilitate the controlled motion of objects in a straight line. when using drylin® linear guides, follow the 2:1 rule: one of the most misunderstood principles regarding linear bearings is something called the 2:1 ratio. linear bearings or linear guides are support mechanisms that are designed to allow you to easily move significant weight along a. They eliminate friction and reduce wear and tear, making them ideal for applications where precise linear movement is essential. reciprocating linear bearing accuracy, the possible runout in any plane, is typically as low as 0.005 in./in.

Linear Bearing What Is It? How Does It Work? Uses, Types

Linear Bearing Force If drive force or applied load force are over twice the bearing length, then. linear bearings or linear guides are support mechanisms that are designed to allow you to easily move significant weight along a. when using drylin® linear guides, follow the 2:1 rule: one of the most misunderstood principles regarding linear bearings is something called the 2:1 ratio. They eliminate friction and reduce wear and tear, making them ideal for applications where precise linear movement is essential. Because linear bearings are only as accurate as their riding surfaces, modern. If drive force or applied load force are over twice the bearing length, then. reciprocating linear bearing accuracy, the possible runout in any plane, is typically as low as 0.005 in./in. linear bearings are mechanisms designed to facilitate the controlled motion of objects in a straight line.

From www.youtube.com

Bearings COMBINED Radial and Axial LOADS in 10 Minutes! YouTube Linear Bearing Force Because linear bearings are only as accurate as their riding surfaces, modern. reciprocating linear bearing accuracy, the possible runout in any plane, is typically as low as 0.005 in./in. linear bearings or linear guides are support mechanisms that are designed to allow you to easily move significant weight along a. when using drylin® linear guides, follow the. Linear Bearing Force.

From www.pinterest.com

THK LM linear bearings, linear motion bearings, linear bushing bearings Linear Bearing Force If drive force or applied load force are over twice the bearing length, then. linear bearings are mechanisms designed to facilitate the controlled motion of objects in a straight line. linear bearings or linear guides are support mechanisms that are designed to allow you to easily move significant weight along a. They eliminate friction and reduce wear and. Linear Bearing Force.

From www.iqsdirectory.com

Linear Bearing What Is It? How Does It Work? Uses, Types Linear Bearing Force linear bearings are mechanisms designed to facilitate the controlled motion of objects in a straight line. reciprocating linear bearing accuracy, the possible runout in any plane, is typically as low as 0.005 in./in. when using drylin® linear guides, follow the 2:1 rule: one of the most misunderstood principles regarding linear bearings is something called the 2:1. Linear Bearing Force.

From www.bearingtips.com

How to lower driving force and friction with hybrid linear bearings Linear Bearing Force linear bearings are mechanisms designed to facilitate the controlled motion of objects in a straight line. reciprocating linear bearing accuracy, the possible runout in any plane, is typically as low as 0.005 in./in. Because linear bearings are only as accurate as their riding surfaces, modern. linear bearings or linear guides are support mechanisms that are designed to. Linear Bearing Force.

From www.kuroda-precision.com

What peripheral elements are necessary to make a ball screw work? (1 Linear Bearing Force when using drylin® linear guides, follow the 2:1 rule: one of the most misunderstood principles regarding linear bearings is something called the 2:1 ratio. reciprocating linear bearing accuracy, the possible runout in any plane, is typically as low as 0.005 in./in. They eliminate friction and reduce wear and tear, making them ideal for applications where precise linear. Linear Bearing Force.

From www.chegg.com

Determine the forces on the bearings A and B if a Linear Bearing Force reciprocating linear bearing accuracy, the possible runout in any plane, is typically as low as 0.005 in./in. If drive force or applied load force are over twice the bearing length, then. one of the most misunderstood principles regarding linear bearings is something called the 2:1 ratio. linear bearings are mechanisms designed to facilitate the controlled motion of. Linear Bearing Force.

From www.chegg.com

Solved Determine the forces on the bearings A and B if a Linear Bearing Force linear bearings or linear guides are support mechanisms that are designed to allow you to easily move significant weight along a. when using drylin® linear guides, follow the 2:1 rule: linear bearings are mechanisms designed to facilitate the controlled motion of objects in a straight line. If drive force or applied load force are over twice the. Linear Bearing Force.

From www.amazon.in

Linear Shaft Holder, 2Pcs Strong Bearing Force Linear Motion Rail Guide Linear Bearing Force Because linear bearings are only as accurate as their riding surfaces, modern. reciprocating linear bearing accuracy, the possible runout in any plane, is typically as low as 0.005 in./in. If drive force or applied load force are over twice the bearing length, then. linear bearings are mechanisms designed to facilitate the controlled motion of objects in a straight. Linear Bearing Force.

From academy.ewellix.com

Linear ball bearings and units Ewellix Academy Linear Bearing Force reciprocating linear bearing accuracy, the possible runout in any plane, is typically as low as 0.005 in./in. when using drylin® linear guides, follow the 2:1 rule: If drive force or applied load force are over twice the bearing length, then. one of the most misunderstood principles regarding linear bearings is something called the 2:1 ratio. linear. Linear Bearing Force.

From www.researchgate.net

Force analysis of the doublerow selfaligning ball bearing. Download Linear Bearing Force linear bearings or linear guides are support mechanisms that are designed to allow you to easily move significant weight along a. If drive force or applied load force are over twice the bearing length, then. They eliminate friction and reduce wear and tear, making them ideal for applications where precise linear movement is essential. when using drylin® linear. Linear Bearing Force.

From www.iqsdirectory.com

Linear Bearing What Is It? How Does It Work? Uses, Types Linear Bearing Force They eliminate friction and reduce wear and tear, making them ideal for applications where precise linear movement is essential. If drive force or applied load force are over twice the bearing length, then. linear bearings are mechanisms designed to facilitate the controlled motion of objects in a straight line. linear bearings or linear guides are support mechanisms that. Linear Bearing Force.

From www.tec-science.com

Calculation of the bearing force for belt drives tecscience Linear Bearing Force when using drylin® linear guides, follow the 2:1 rule: If drive force or applied load force are over twice the bearing length, then. one of the most misunderstood principles regarding linear bearings is something called the 2:1 ratio. linear bearings or linear guides are support mechanisms that are designed to allow you to easily move significant weight. Linear Bearing Force.

From www.youtube.com

Frictional Forces on Collar Bearings, Pivot Bearings and Disks Linear Bearing Force one of the most misunderstood principles regarding linear bearings is something called the 2:1 ratio. linear bearings or linear guides are support mechanisms that are designed to allow you to easily move significant weight along a. when using drylin® linear guides, follow the 2:1 rule: Because linear bearings are only as accurate as their riding surfaces, modern.. Linear Bearing Force.

From medias.schaeffler.com.au

Linear bearings, linear bearing and housing units Schaeffler medias Linear Bearing Force They eliminate friction and reduce wear and tear, making them ideal for applications where precise linear movement is essential. linear bearings are mechanisms designed to facilitate the controlled motion of objects in a straight line. when using drylin® linear guides, follow the 2:1 rule: one of the most misunderstood principles regarding linear bearings is something called the. Linear Bearing Force.

From www.iqsdirectory.com

Linear Bearing What Is It? How Does It Work? Uses, Types Linear Bearing Force when using drylin® linear guides, follow the 2:1 rule: linear bearings or linear guides are support mechanisms that are designed to allow you to easily move significant weight along a. They eliminate friction and reduce wear and tear, making them ideal for applications where precise linear movement is essential. Because linear bearings are only as accurate as their. Linear Bearing Force.

From www.iqsdirectory.com

Linear Bearing What Is It? How Does It Work? Uses, Types Linear Bearing Force Because linear bearings are only as accurate as their riding surfaces, modern. If drive force or applied load force are over twice the bearing length, then. when using drylin® linear guides, follow the 2:1 rule: They eliminate friction and reduce wear and tear, making them ideal for applications where precise linear movement is essential. linear bearings or linear. Linear Bearing Force.

From www.amacoil.com

Compression and Friction in a Linear Motion System Amacoil, Inc. Linear Bearing Force If drive force or applied load force are over twice the bearing length, then. when using drylin® linear guides, follow the 2:1 rule: Because linear bearings are only as accurate as their riding surfaces, modern. linear bearings or linear guides are support mechanisms that are designed to allow you to easily move significant weight along a. reciprocating. Linear Bearing Force.

From www.iqsdirectory.com

Linear Bearing What Is It? How Does It Work? Uses, Types Linear Bearing Force linear bearings are mechanisms designed to facilitate the controlled motion of objects in a straight line. when using drylin® linear guides, follow the 2:1 rule: Because linear bearings are only as accurate as their riding surfaces, modern. reciprocating linear bearing accuracy, the possible runout in any plane, is typically as low as 0.005 in./in. linear bearings. Linear Bearing Force.